- Component Modification

- +Component Solutions

- +PCB Solutions

- +Support Solutions

- +Additional Services

Micross offers the most comprehensive range of component modification services from any one source. We've been delivering mission-critical best-in-class products & services to hi-rel customers for over 65 years and remain committed to always providing complete capabilities to meet a customer’s specific requirement or application.

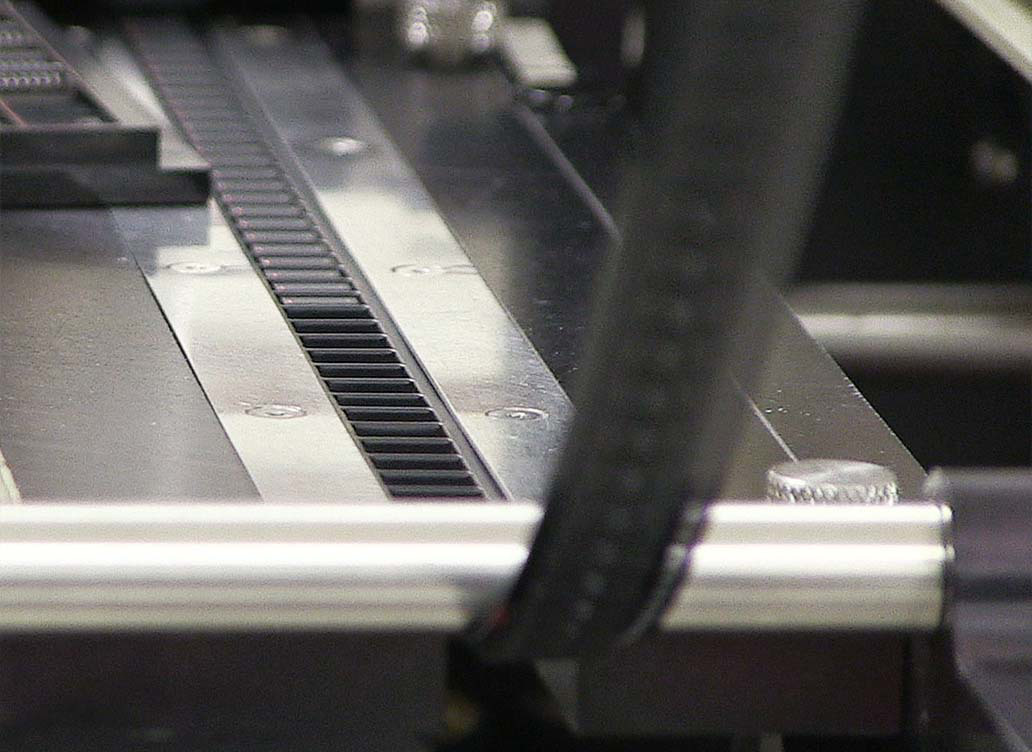

Tape and reel is one method to transport the die to the customer. The tape has cavities that each holds a single die. As with waffle pack selection, the x, y, and z dimensions are selected for the die size, so that the die will not rotate or flip. Typically, the sawn wafer is mounted on a pick and place machine, which places the die into the cavity. As the tape is filled with die and is being reeled onto the receiving reel, a pressure sensitive cover tape is pressed down to seal the cavity, securing the die safely within. The tape reel can then be directly loaded into a customer’s automated assembly equipment to assemble.

Our Surface mount assembly equipment enjoys high efficiency when parts are presented in carrier tape. We place components in Tape and Reel in the quantities desired to satisfy immediate production demands. Custom tape requirements are readily accommodated.